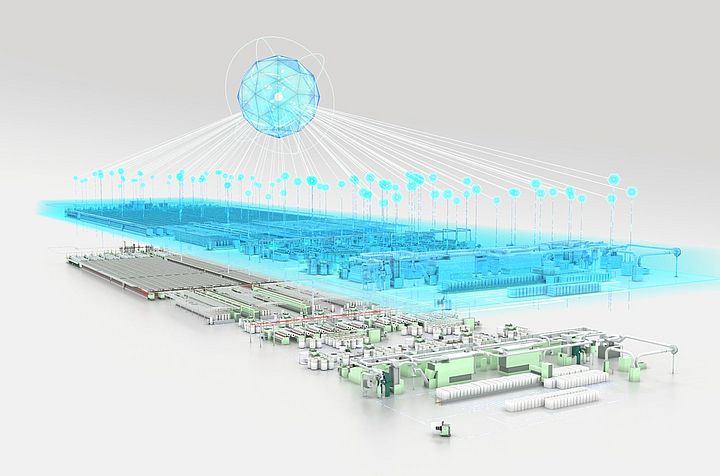

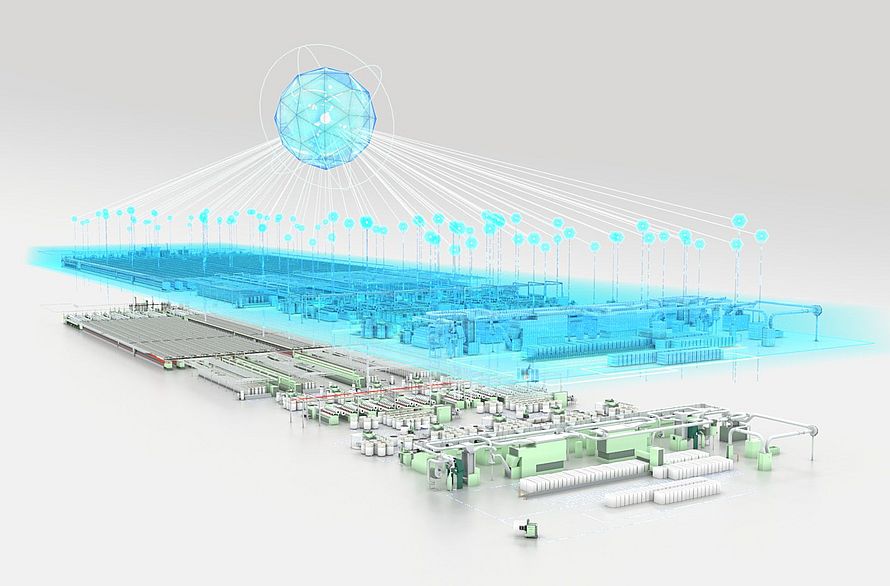

The Smart Path Into the Digital Future

For spinning mills, ESSENTIAL means a better fiber yield and noticeably optimized production. The digital platform provides a solid basis for decision-making at all levels – from management to machine operation. It is the foundation for future-proof and fully automated yarn production.

Hundreds of spinning mills worldwide already rely on Rieter’s digital solution. Anyone who takes a look at ESSENTIAL, Rieter’s mill management system, will immediately see the added value. The platform connects machines and organizes, compares, and visualizes data, thus enabling maximum transparency in the production process.

In real time, ESSENTIAL shows how efficiently the spinning mill is running and how much yarn is currently being produced. Whether production, efficiency, energy consumption, or quality – all relevant key figures are always in sight. If deviations from the target value occur, the system immediately provides specific recommendations for action. This information helps to identify potential for optimization during the current shift and enables immediate implementation. This makes spinning mills fit for the future.

Different modules for different requirements

The digital platform ESSENTIAL consists of three modules:

- ESSENTIALbasic provides basic functions for a more efficient work routine, such as access to the web shop, operating instructions, and Rieter expertise.

- ESSENTIALmonitor monitors production in real time and detects weak points. It tracks data such as energy consumption, quality, productivity, and maintenance.

- ESSENTIALoptimize goes one step further. The module uses artificial intelligence (AI) for data analysis and derives concrete solutions from it. Mill managers receive specific recommendations for action to further optimize their yarn production.

any location.

With the next generation of machines, all Rieter machines will be geared toward digital spinning mills as the standard. This means even more transparency, higher efficiency, and improved profitability thanks to comprehensive digital process monitoring and control. Retrofitting with ESSENTIAL is an effective solution that is customized and tailored to the existing machines in the spinning mill.

Unlock the full potential with ESSENTIALoptimize

ESSENTIALoptimize brings the digital technologist to the spinning mill. The software combines AI methods with Rieter’s textile technology expertise to find faults more quickly and suggest possible solutions. With ESSENTIAL, the supervisor can pass these suggestions on to the operating personnel directly as a work order.

For example, if yarn cuts occur on the winding machine more frequently, this often indicates hidden quality problems in the upstream process stages. A typical example is thick places in the sliver. Based on measurements taken by the Rieter Quality Monitor, ESSENTIALoptimize visualizes these thick places simultaneously for the card, comber, and draw frame – over an impressive period of nine production shifts.

Working on the basis of clear rules, defined limit values, and the evaluation of historical machine data, ESSENTIALoptimize detects and reports these types of errors long before they appear in the yarn. This not only saves raw material but also optimizes control, improves safety, and increases the profitability of the spinning mill.

Quickly detect and correct malfunctioning spindles

ESSENTIALoptimize also visualizes the winder quality data collected by Ring-Winder Connect and precisely assigns it to the spinning position of the connected ring or compact-spinning machine. If the quality is not satisfactory, an LED signals to the operator that immediate action is required, thus enabling a prompt and focused response.

An optional roving stop automatically interrupts the roving feed. The detection of alarm cops and off-standard cops is a unique feature on the market. Alarm cops have faulty yarn, so it is necessary to stop the spinning position immediately.

Offstandard cops come from spinning positions that produce “tolerable quality yarn” but still have a below-average quality level.

Monitor energy consumption and quality

In addition to production data, energy consumption and quality data can be accessed in ESSENTIAL. For quality data, there are various sources, including the Rieter quality monitors for the card, draw frame, and combers, as well as the yarn clearers of rotor spinning and air-jet spinning machines.

In addition, ESSENTIAL allows for central viewing and evaluation of data from the piecing robot ROBOspin on ring and compact-spinning machines, as well as from the robots on rotor spinning and air-jet spinning machines.

Basis for the future

Rieter is continuously developing further solutions to optimize the spinning process and ease the workload for spinning mill employees. ESSENTIAL makes spinning mills not only more transparent and efficient, but also fit for the future.