Redefining the Spinning Mill

Automatic can transport takes over monotonous and physically demanding tasks.

The future is within reach: In 2027, fully automated Rieter spinning mills with only three operators for every 10 000 spindles will become a reality. This means maximum efficiency with minimum personnel costs. Smart automation solutions are paving the way, such as the new bale and can transport system and a fully automated packaging line.

Short-staple spinning mills are under increasing pressure due to rising production costs, a growing shortage of skilled workers, and increasing traceability requirements. As a result, the current spinning mill model is hardly economically viable anymore. A major change is necessary.

Full automation becomes a reality

A new generation of spinning mills is showing what will be possible in the future – just three skilled workers for every 10000 spindles and shift to produce 1.9 tons of yarn. This is equivalent to automating two-thirds of the work that was previously done manually. This increases efficiency massively, but also makes yarn production as a whole competitive again. Automation is therefore no longer a futuristic dream – it is a prerequisite for realigning the industry.

Implementation in stages

At ITMA in Singapore, Rieter will be showcasing new automation solutions that pave the way step-by-step to fully automated production from 2027 onwards. With the following portfolio, customers can already make their processes more productive today:

- efficient bale transport by means of a driverless transport system,

- flexible transport of the corresponding size cans between machines by means of a driverless transport system, and

- packaging solutions, including steaming, palletizing, and labeling.

Can transport is a significant improvement, as it takes over physically demanding tasks and thus noticeably reduces the strain on operating personnel. At the same time, it increases process reliability and efficiency throughout the entire production process.

The automated packaging line, from packing the yarn packages to palletizing and labeling, is also raising the bar. It replaces numerous manual tasks with high-precision, fully automated processes.

These new automation solutions make it possible to start using full automation and to boost its acceptance in spinning mills. At the same time, they provide valuable experience for further changes.

Vision 2027: fully automated production process

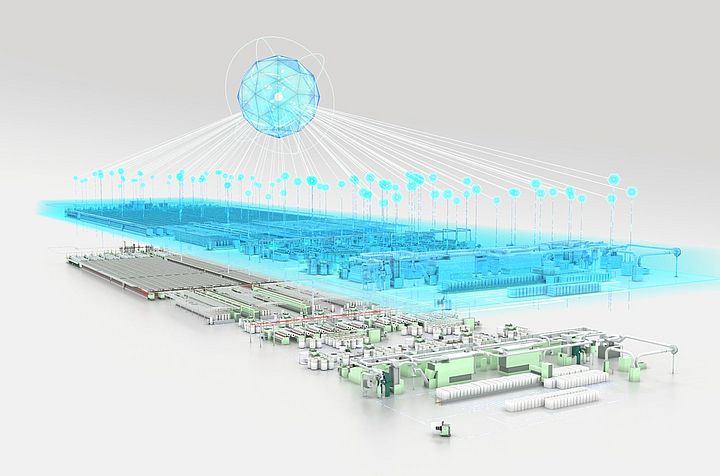

The year 2027 will see a milestone in textile automation: the unveiling of a fully automated reference line. The vision goes far beyond conventional approaches. The heart of this line is a fully automated, integrated production process enabled by intelligent, digitally networked systems.

Automation already comes into play with the raw material: the complex and potentially dangerous manual removal of steel straps from bales is being replaced by robot-assisted solutions. And it ends with the packed yarn package leaving the spinning mill ready for shipment.

A seamless connection: automation and digitization

There is no automation without digitization. Using the digital platform ESSENTIAL ensures full control of automation solutions and makes it possible to track all process steps from start to finish.

The platform collects all the relevant data, which is then available in real time. This transparency is a decisive competitive advantage, especially in terms of the traceability of textile products.

Profitable investment with foresight

No matter how fascinating state-of-the-art robotics, digital networking, and autonomous systems are, in the end, one question matters: Is the investment worthwhile? The answer is clear: Yes! Introducing fully automated systems is much more than a short-term cost experiment. It is a strategic investment in efficiency, quality assurance, and future viability.

The operating costs – especially personnel costs, error costs, waste, and downtimes – account for a significantly higher share over the life cycle of a system than the initial investment in technology.

Automation reduces dependence on human resources, ensures reproducible quality, and enables stable, predictable production processes – independent of shift or location.

Those who invest in this technology today are laying the foundation for tomorrow’s success.