Anleitung zum richtigen Schleifen

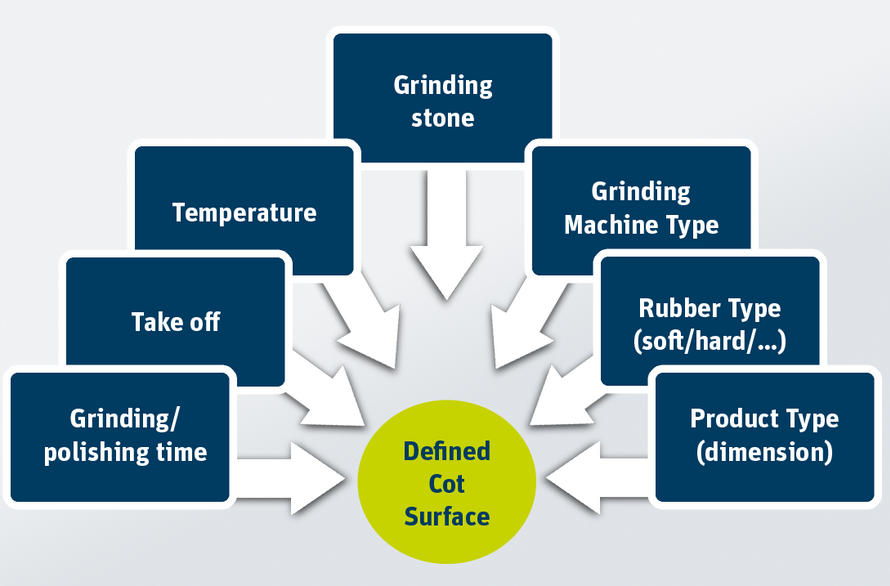

Eine verbesserte Garnqualität ist für heutige Spinnereien ein wesentlicher Wettbewerbsvorteil. Accotex-Bezüge sind Standard-Frontbezüge, die von den Maschinenherstellern sowohl für reguläre als auch für Kompaktspinnmaschinen zugelassen sind. Die Verbesserung der Garnwerte (Gleichmäßigkeit, dünne Stellen und dicke Stellen) erfordert einen hochwertigen weichen Bezug; die Leistung dieses Bezugs hängt jedoch weitgehend von der richtigen Vorbereitung der Bezugsfläche ab.