正确研磨的说明

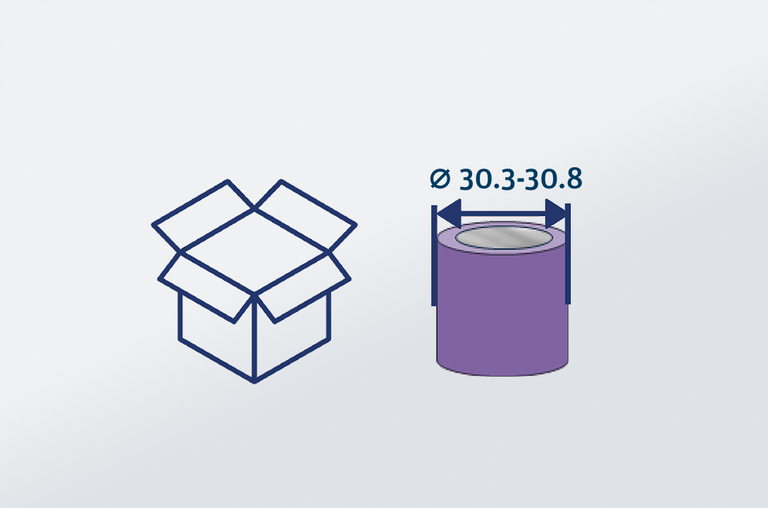

提升纱线品质是当今纺纱企业构筑市场竞争优势的核心环节。Accotex胶辊作为经设备制造商认证的标准胶辊,全面适用于传统纺纱机与紧密纺纱机。要优化纱线关键指标(条干均匀度、细节、粗节),必须采用高品质软质胶辊——而此类胶辊的性能表现,很大程度上取决于其表面是否经过妥善处理。

提升纱线品质是当今纺纱企业构筑市场竞争优势的核心环节。Accotex胶辊作为经设备制造商认证的标准胶辊,全面适用于传统纺纱机与紧密纺纱机。要优化纱线关键指标(条干均匀度、细节、粗节),必须采用高品质软质胶辊——而此类胶辊的性能表现,很大程度上取决于其表面是否经过妥善处理。

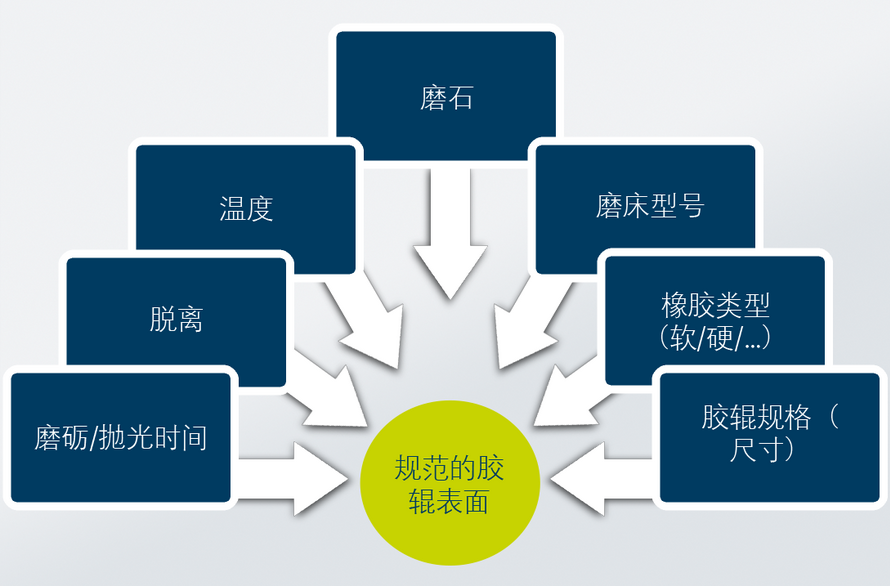

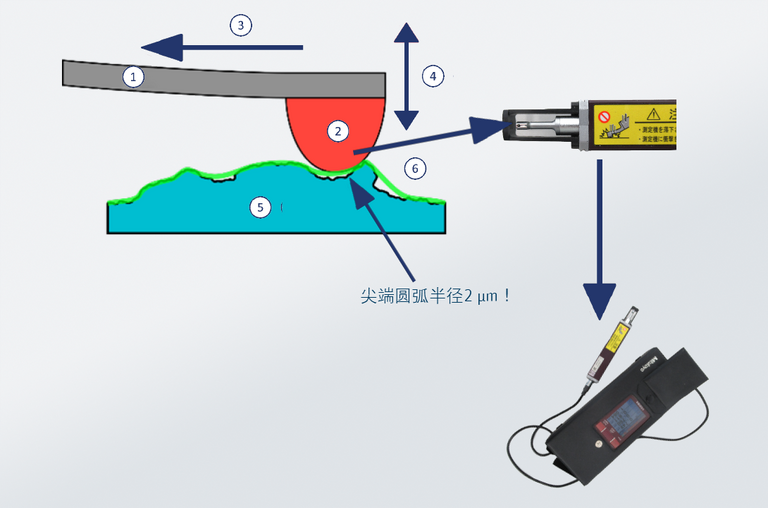

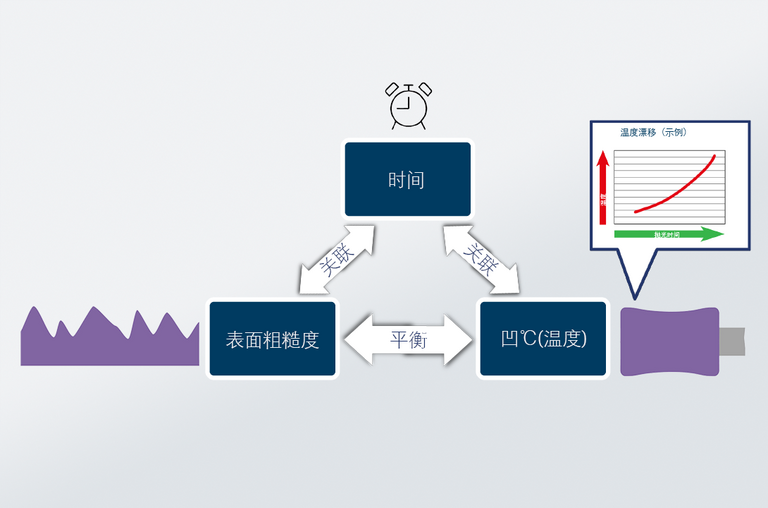

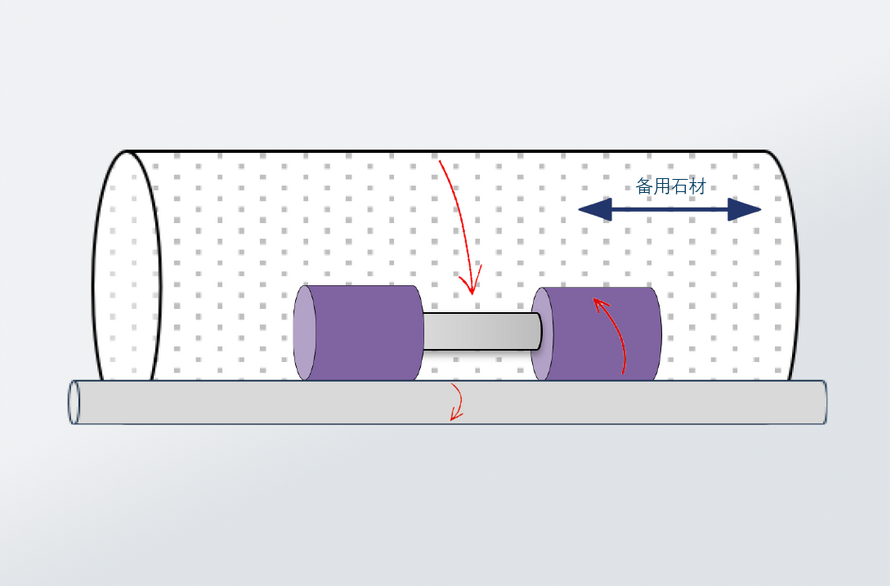

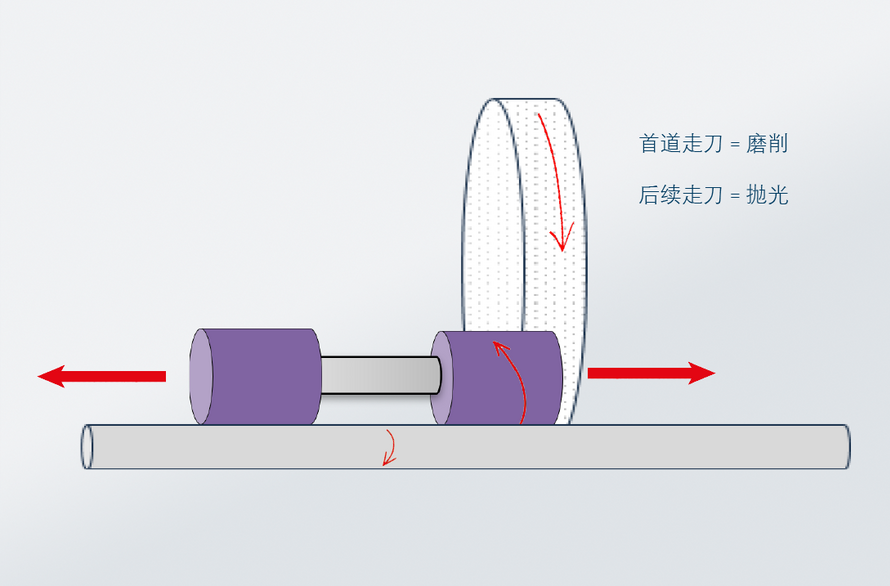

为确保胶辊获得优异性能,其表面粗糙度必须控制在精准范围。在特定工艺场景下,可采用紫外线光照处理作为胶辊表面处理的可行方案。

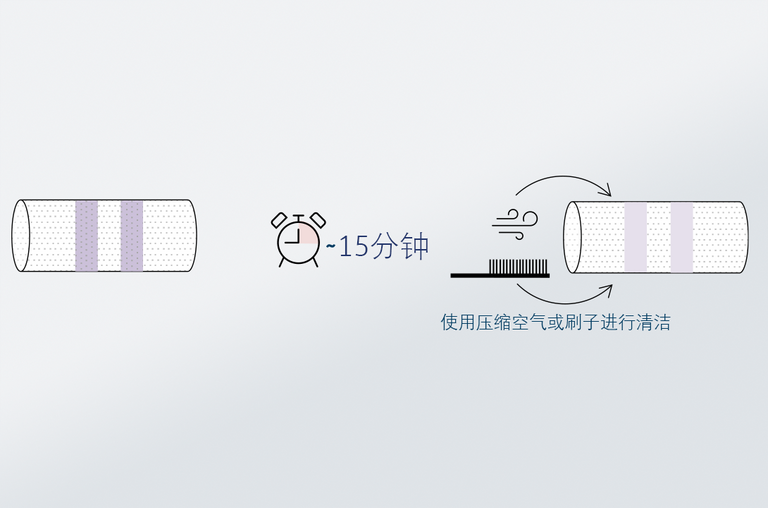

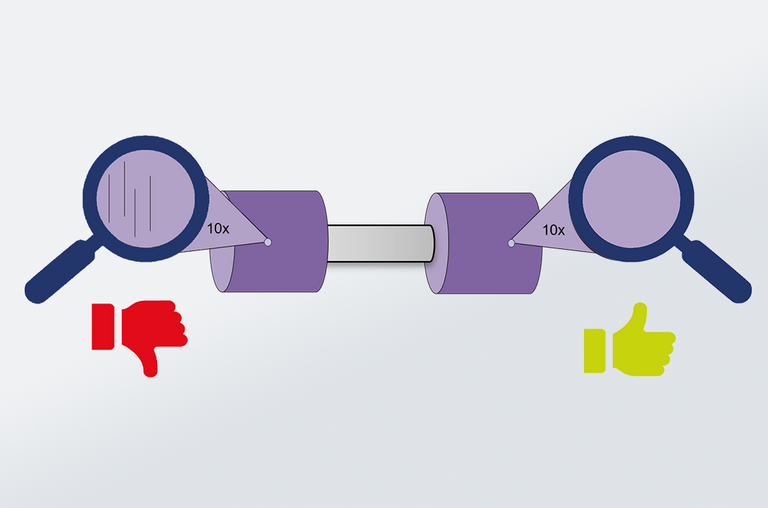

磨砺后的胶辊表面必须洁净,无残留磨屑与磨床划痕。

磨砺后的胶辊具有合适的表面粗糙度(Ra值)。

检查设备:

The grinding results that should be achieved are:

| Type | Removel (OD) | Targeted roughness [µRa] (cold surface) |

| Ring spinning | 0.3 mm | 0.8 – 1.0 |

| Air-Jet spinning | 0.3 mm | 0.6 – 0.8 |

Grinding intervals:

| Hardness | Type | Recommend grinding interval |

| Soft cots | Ring spinning | 1 - 3 months |

| Medium cots | Ring spinning | 1 - 3 months |

| Hard cots | Ring spinning | 4 - 5 months |

| Soft cots | Air-Jet spinning | 7 - 15 days |

| Hard cots | Air-Jet spinning | 4 - 5 months |

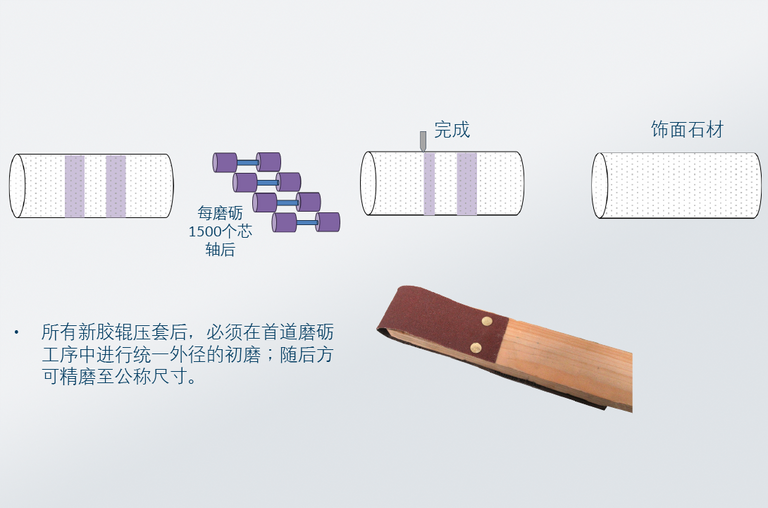

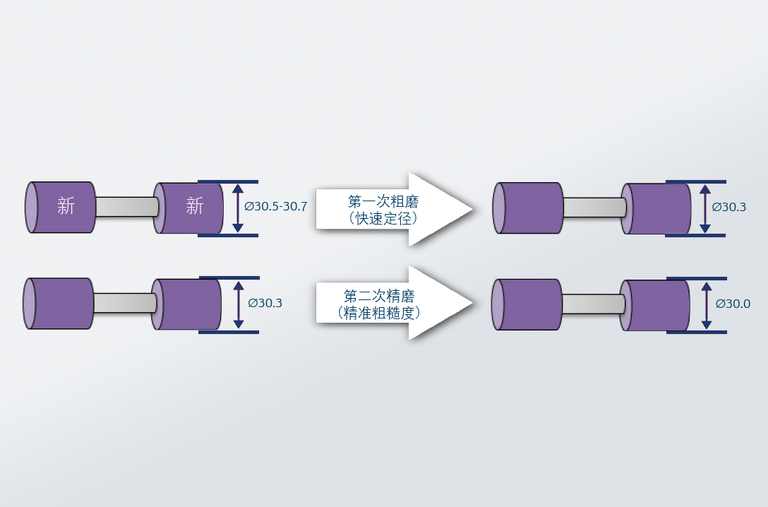

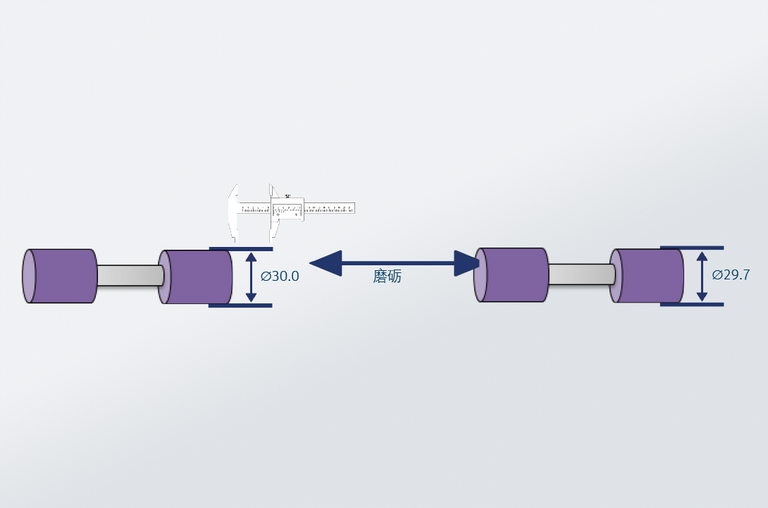

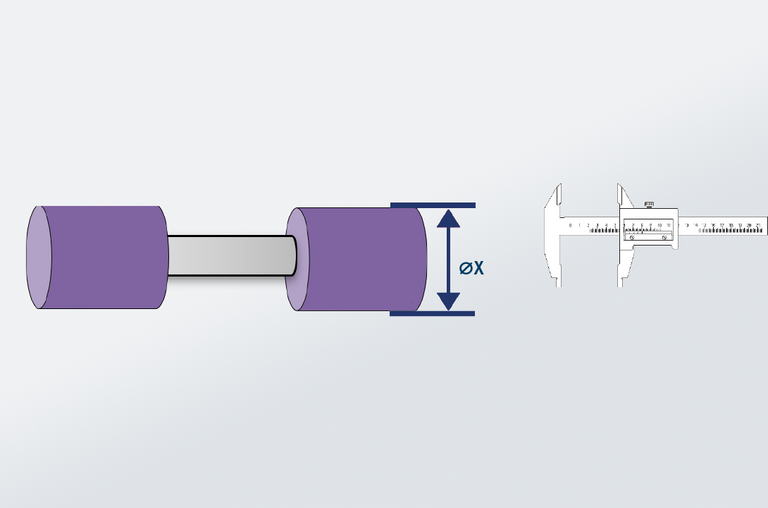

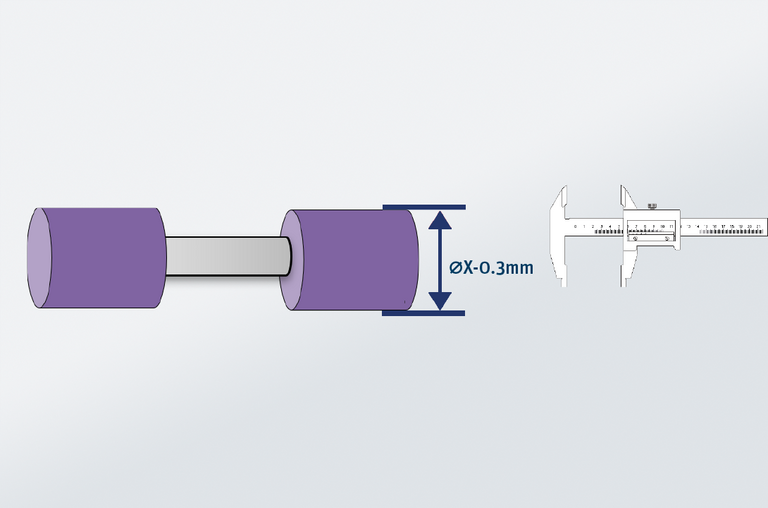

1、磨砺前先测量胶辊外径。

2、建议初始参数设置如下:

a. 使用粒度120目、孔隙度10级的砂轮时:

b. 使用粒度80目、孔隙度14级的砂轮时:

*总接触时间 = 磨削时间 + 抛光时间

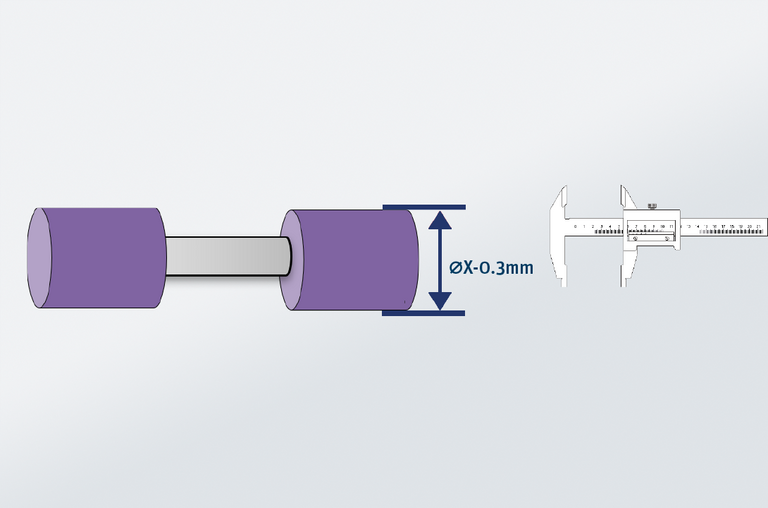

3、磨砺后测量胶辊外径;在常温表面测得数值应减少0.3毫米。

若采用自动测量系统,需定期用卡规校验测量值。建议选用“定尺寸磨削“模式。

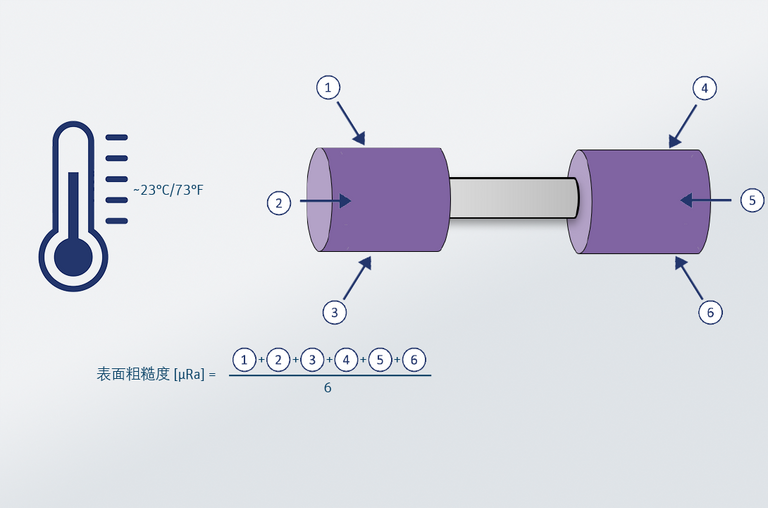

4、当直径减磨量达到0.3毫米后,请待胶辊表面冷却至常温状态后测量其表面Ra值。

半自动或全自动磨床参数:

应达到的磨砺效果如下:

| 纺纱类型 | 外径减磨量 (OD) | 常温表面)目标粗糙度 [µRa] |

| 环锭纺 | 0.3 mm | 0.8 – 1.0 |

| 环锭纺 | 0.3 mm | 0.6 – 0.8 |

磨砺周期:

| 硬度 | 纺纱类型 | 建议磨砺周期 |

| 软质胶辊 | 环锭纺 | 1 - 3 个月 |

| 中硬胶辊 | 环锭纺 | 1 - 3 个月 |

| 硬质胶辊 | 环锭纺 | 4 - 5 个月 |

| 软质胶辊 | 环锭纺 | 7 - 15 天数 |

| 硬质胶辊 | 环锭纺 | 4 - 5 个月 |

1、磨砺前先测量胶辊外径。

2、建议初始参数设置如下:

使用粒度120目、孔隙度14级的砂轮时:

3、磨砺后测量胶辊外径;在常温表面测得数值应减少0.3毫米。

4、当直径减磨量达到0.3毫米后,请待胶辊表面冷却至常温状态后测量其表面Ra值。